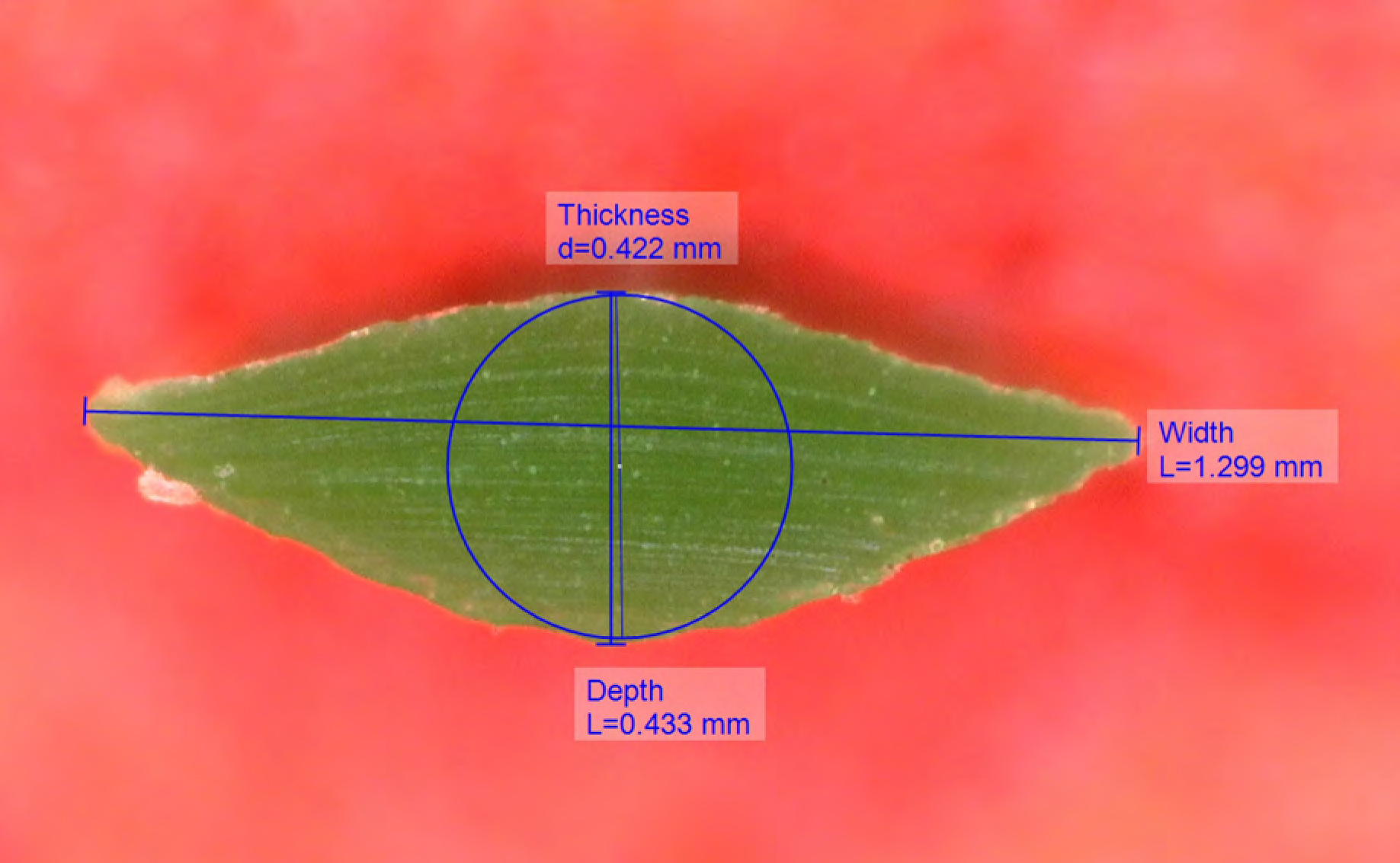

1. Yarn Thickness

Yarn thickness refers to the diameter or thickness of the individual fibers that make up the artificial grass. It is typically measured in micrometers (μm).

-

Durability and wear resistance

Thicker yarns often contribute to the durability and wear resistance of the artificial grass. The increased thickness provides more material to withstand the friction and abrasion caused by foot traffic and other physical activities. As a result, turf with thicker yarns may have a longer lifespan.

-

Resilience and Recovery

Thicker yarns can enhance the resilience of the artificial grass fibers. This means that the fibers are better able to recover their shape after being compressed or flattened during play. Improved resilience contributes to the turf's ability to maintain its appearance and performance over time.

-

Manufacturer Specification

It's important to consider the specifications provided by the manufacturer regarding yarn thickness. Different manufacturers may offer a variety of yarn options, and understanding the characteristics of each can help in selecting the most suitable artificial grass for a specific application.

-

Heat Retention

The thickness of the yarn can impact the heat retention characteristics of the artificial grass. Thicker yarns may have a greater surface area, potentially leading to increased heat absorption.

In summary, yarn thickness is a key factor in determining the visual and functional characteristics of artificial grass. The choice of thickness should align with the intended use of the turf, considering factors such as aesthetics, durability, comfort, and environmental conditions.

2. Yarn Shape

The shape of artificial grass yarn refers to the cross-sectional profile or geometry of the individual fibers that make up the turf. Yarn shape is a crucial characteristic that influences various aspects of the artificial grass, including its appearance, performance, resilience, and functionality. Here are some common yarn shapes used in artificial grass and their properties:

D Shaped or Oval Shaped Yarns

Thicker yarns often contribute to the durability and wear resistance of the artificial grass. The increased thickness provides more material to withstand the friction and abrasion caused by foot traffic and other physical activities. As a result, turf with thicker yarns may have a longer lifespan.

Diamond Shaped Yarns

Diamond-shaped yarns have a cross-sectional profile resembling a diamond or rhombus.

Properties:

Enhanced Durability: The diamond shape can contribute to the strength and durability of the yarn, making it suitable for high-traffic areas.

Texturing: The textured surface may help reduce glare and enhance the overall appearance of the artificial grass.

Omega or W shaped Yarns

Improved Resilience: The Omega shaped design can enhance the yarn's ability to bounce back and recover after compression, contributing to better resilience.

Impact on appearance: Such yarns have a direct impact on the visual aesthetics of the artificial grass. Thicker yarns tend to create a lush and dense appearance, mimicking the look of natural grass.Friction Resistance: The curved shape may reduce friction between fibers, potentially improving the turf's durability.

S-Shaped Yarns

S-shaped yarns have a double curve, resembling the letter 'S.'

Natural Appearance: S-shaped yarns are designed to replicate the appearance of natural grass blades, providing a realistic look.

Enhanced Resilience: The double curve can contribute to improved resilience and recovery, ensuring that the fibers maintain their shape and structure.

Softness: S-shaped yarns may offer a softer feel underfoot, enhancing comfort during use.

C-Shaped Yarns

C-shaped yarns have a curved or C-shaped profile

Improved Resilience: The C-shaped design can enhance the yarn's ability to bounce back and recover after compression, contributing to better resilience.

Reduced Shine: C-shaped yarns are often designed to reduce glare or shine, providing a more natural appearance under different lighting conditions. Friction Resistance: The curved shape may reduce friction between fibers, potentially improving the turf's durability.

Flat Yarn

Flat yarns have a flattened or ribbon-like cross-sectional profile

Natural Appearance: Flat yarns are often chosen for their ability to mimic the look of natural grass blades. They provide a broad surface that reflects light in a way similar to real grass.

Softness: Flat yarns can contribute to a softer feel underfoot, enhancing comfort for users.

Durability: The broader surface of flat yarns may enhance wear resistance and durability.

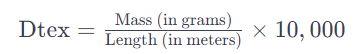

3. Dtex

Dtex, short for decitex, is a unit of measurement used to express the linear mass density of fibers. Dtex is defined as the mass in grams per 10,000 meters of the fiber or yarn. Dtex is a measure of linear mass density, representing the weight of a fiber in grams per 10,000 meters.

Calculation: Dtex is indeed the mass in grams per 10,000 meters of the fiber or yarn. The correct calculation is as follows:

So, if a yarn has a Dtex value of 10,000, it means that a 10,000-meter length of that yarn would weigh 10,000 grams (or 10 kilograms).

In the context of artificial grass, the Dtex value of yarns provides information about their thickness. Higher Dtex values generally indicate thicker and more robust yarns, while lower values suggest finer and lighter fibers.

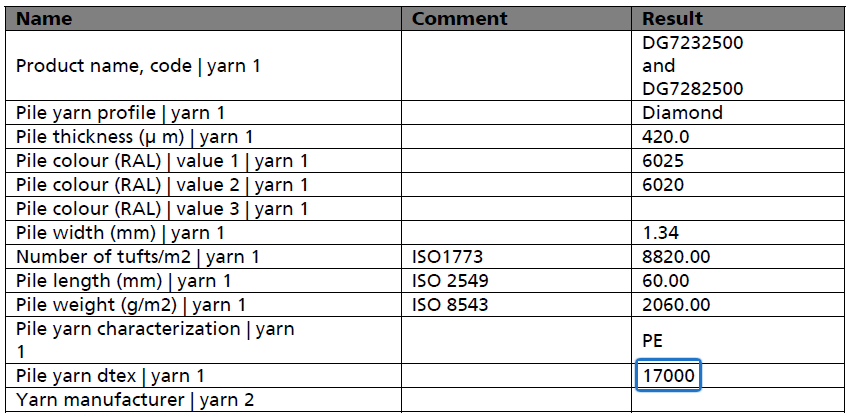

Dtex values of the products will be mentioned in the FIFA certificate as mentioned in the below table:

Conclusion: Yarns with higher Dtex values are often associated with increased durability and resilience. They may be suitable for high-traffic areas or applications where the turf needs to withstand heavy use.

4. Unit Dtex

Unit Dtex is the Dtex of a single yarn per stitch. Usually, the combination of yarns in a stitch varies between 6 yarns and 8 yarns for the various models of football grass. The "number of yarns per stitch" is a measure that describes how many individual yarns or threads are involved in the creation of a single stitch in a fabric. Unit Dtex is a major factor which considers the quality of yarn as this can be easily mis interpreted with Dtex.

Can be explained with an example: There are products with 16000 Dtex and 14000 Dtex. While we consider only the Dtex factor, 16000 Dtex material will showcase as higher quality. But the comparison should also be done with “unit Dtex”. There are products with 16000 Dtex having 8 yarns per stitches (Unit Dtex: 16000/8=2000) and 14000 Dtex having 6 yarns per stitches (Unit Dtex:14000/6: 2333). So, the individual yarn quality of 14000Dtex material will be higher which can have more durability than 16000 Dtex material.

5. Density

-

Definition

The density factor represents the concentration or number of synthetic fibers within a defined area of the artificial grass. It is often expressed as the number of stitches or tufts per unit of length and width.

-

Calculation

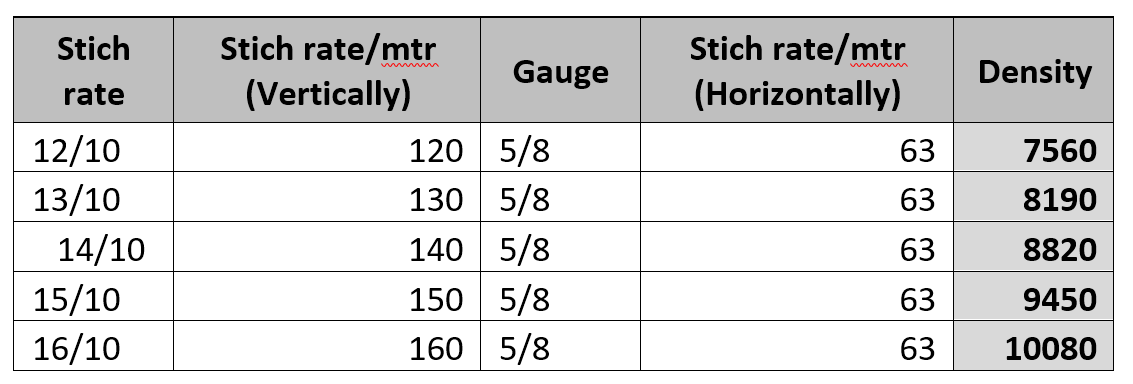

The density factor is calculated by dividing the total number of fibers or stitches on the artificial grass by the total area it covers. The result is typically presented as a density per square meter or square foot.

-

Impact on appearance

A higher density factor generally leads to a fuller and more lush appearance of the artificial grass. The surface looks more closely packed with fibers, resembling natural grass more closely.

-

Durability

Artificial grass with a higher density factor tends to be more durable. The increased number of fibers provides better resistance to wear and tear, making the turf suitable for areas with higher foot traffic.

6. Stitch Rate

Stitch rate is defined as the number of stitches or tufts of yarn per unit of length along the width or length of the artificial grass. It is often expressed as stitches per meter (or stitches per foot).

-

Calculation

The stitch rate is calculated by counting the number of stitches or tufts within a specified distance (typically one meter or one foot) along the width or length of the artificial grass. The result is then expressed as a numerical value representing the stitch rate.

-

Impact on density

The stitch rate directly influences the density of the artificial grass. A higher stitch rate means more stitches per unit length, resulting in a denser and fuller appearance.